Exhaust cutout valves optimize gas flow, boost engine power & torque, and customize exhaust sound in vehicles, ideal for performance driving. Strategic placement considers exhaust system design, backpressure, weight distribution, and interactions with intakes & brakes to enhance efficiency and control. Correct installation is crucial, avoiding airflow disruption or wiring errors that hinder performance.

In today’s automotive landscape, optimizing engine performance and efficiency is paramount. Exhaust cutout valves play a pivotal role in achieving this by controlling exhaust gas flow, enhancing power and torque. This article delves into the intricacies of these valves, guiding you through the key factors for their optimal placement. From understanding their fundamental role to avoiding common mistakes, we equip you with the knowledge to maximize the benefits of exhaust cutout valves.

- Understanding Exhaust Cutout Valves: Their Role and Benefits

- Key Factors to Consider for Optimal Placement

- Best Practices and Common Mistakes to Avoid

Understanding Exhaust Cutout Valves: Their Role and Benefits

Exhaust cutout valves are specialized automotive components designed to control and manipulate exhaust gas flow within a vehicle’s engine system. These valves play a crucial role in enhancing engine performance, especially during specific driving conditions. By allowing for precise adjustment of exhaust gas release, they offer several key benefits that contribute to overall vehicle dynamics.

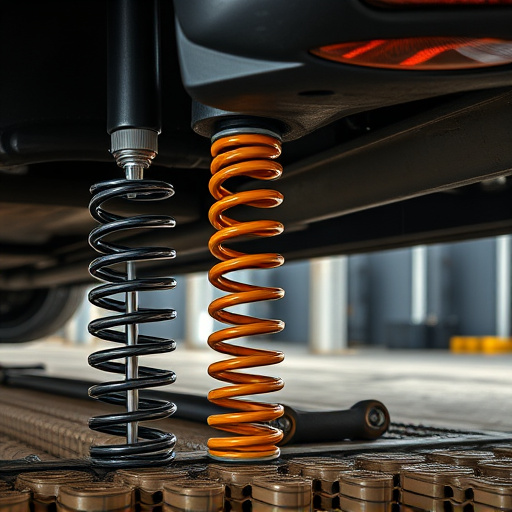

One of the primary advantages is their ability to reduce backpressure in the exhaust system, which can significantly boost engine power and torque, particularly at higher RPMs. This enhancement is particularly noticeable when paired with performance intake components or coilover kits. Additionally, exhaust cutout valves enable drivers to customize the sound of their vehicle’s exhaust tips, offering a unique tuning experience. Their strategic placement and control over exhaust flow can also improve fuel efficiency and lower emissions, making them valuable assets for both everyday driving and track days.

Key Factors to Consider for Optimal Placement

When determining the best placement for exhaust cutout valves to achieve maximum effect, several key factors come into play. Firstly, consider the layout and design of your vehicle’s exhaust system. The positioning of the cutouts should align with areas where backpressure is significant, such as near headers or manifolds, to optimize gas flow and improve engine performance. Secondly, take into account the vehicle’s overall dynamics, including weight distribution and center of gravity, which can impact how exhaust gases are expelled and affect handling characteristics.

Additionally, think about the interaction between the exhaust cutout valves and other components like intake systems and brake pads. Proper placement can enhance the overall efficiency of your vehicle by ensuring smooth gas exchange while also managing heat dissipation and maintaining optimal braking performance. Balancing these elements requires a strategic approach to get the most out of your exhaust cutout valves, ultimately contributing to improved engine output and vehicle control.

Best Practices and Common Mistakes to Avoid

When it comes to installing exhaust cutout valves for optimal performance in your vehicle, there are best practices to follow and common mistakes to avoid. One of the key considerations is understanding where to place these valves within your car’s air intake and exhaust systems. Exhaust cutout valves are designed to redirect airflow, improving engine performance and sound. The best placement is often near the back of the vehicle, close to the exhaust tips. This strategic positioning ensures that the valve can efficiently control the flow of exhaust gases, enhancing power delivery and throttle response.

A common mistake is misplacing these valves or installing them without considering their impact on overall system dynamics. Avoid mounting exhaust cutout valves too far from the engine or in positions that disrupt the airflow path of your performance exhaust system. Additionally, ensure proper wiring and control module integration for seamless operation and precise tuning. By adhering to these guidelines, you can maximise the benefits of exhaust cutout valves, enhancing both the functionality and sound of your air intake systems.

Exhaust cutout valves are powerful tools for enhancing vehicle performance and engine health. By understanding their functionality and strategically placing them, you can achieve optimal results. Consider factors like engine layout, exhaust flow patterns, and desired sound levels to determine the best placement for maximum effect. Avoid common mistakes such as improper alignment or inadequate sealing, and follow best practices for long-lasting, efficient exhaust cutout valve performance. Remember, the right placement makes all the difference in unlocking your vehicle’s full potential.