Exhaust cutout valves are essential for vehicle performance control, adjusting gas flow to modify exhaust note, power, and efficiency. Regular inspection and maintenance prevent wear, corrosion, and damage, ensuring optimal valve operation and extending component life. Cleaning, lubrication, and gasket/seal replacement enhance reliability, maximizing engine efficiency.

Exhaust cutout valves are essential components in various industrial settings, ensuring safe and efficient gas ventilation. This article offers a comprehensive guide on maintaining these critical systems. We’ll first demystify their functionality and importance, then provide practical tips for regular inspection, cleaning, and maintenance to prevent costly breakdowns. By following these guidelines, you can extend the lifespan of exhaust cutout valves, enhancing operational reliability and safety in your workplace. Learn how to keep these vital mechanisms in top condition using simple yet effective practices.

- Understanding Exhaust Cutout Valves: Basics and Functionality

- Regular Inspection: Key Steps for Prevention of Issues

- Efficient Cleaning and Maintenance Practices for Longevity

Understanding Exhaust Cutout Valves: Basics and Functionality

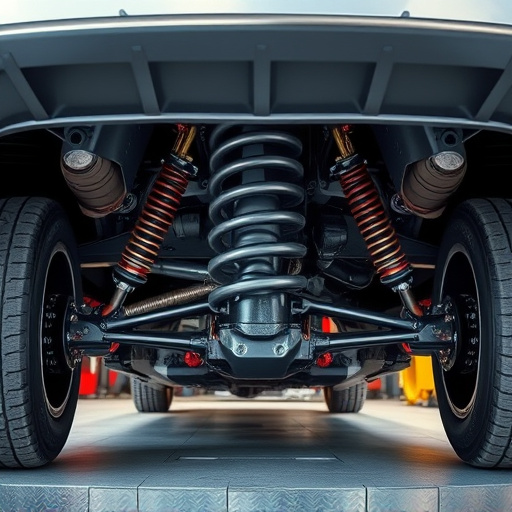

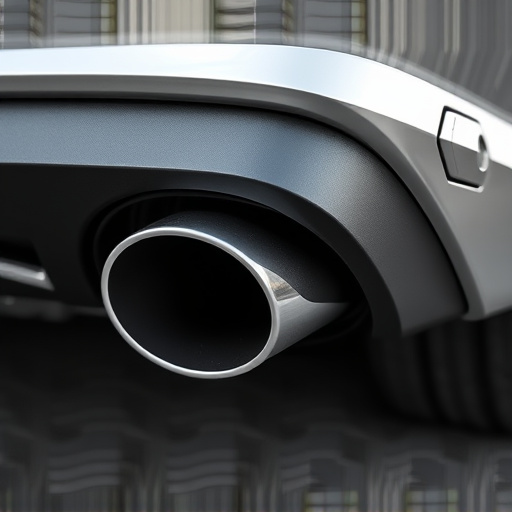

Exhaust cutout valves are essential components in a vehicle’s exhaust system, responsible for controlling and manipulating gas flow. These valves play a critical role in enhancing vehicle performance by allowing for precise adjustments to the exhaust note, power delivery, and overall efficiency. They function as a sort of gate or shutter, opening and closing to regulate the escape of gases from the engine compartment. This control is particularly useful during various driving conditions, such as during acceleration or when specific emission standards need to be met.

Understanding how these valves operate is crucial for maintaining optimal vehicle performance. Exhaust cutout valves are typically actuated by electrical or pneumatic systems, which respond to signals from the engine control unit (ECU). By adjusting the valve’s position, it can direct gases either through the mainstream exhaust system or divert them through alternative paths, like a resonator or muffler. This manipulation affects noise levels, backpressure, and the overall performance of the vehicle, including its brakes and intake components. Regular maintenance ensures these valves function as intended, contributing to both efficient operation and reduced environmental impact.

Regular Inspection: Key Steps for Prevention of Issues

Regular inspection is a critical step in maintaining the reliability and longevity of exhaust cutout valves. It involves a thorough check for any signs of wear, corrosion, or damage. This process should include visually inspecting all components for cracks, rust, or loose connections. Additionally, checking the condition of gaskets, seals, and other movable parts is essential to ensure they are in good shape and functioning optimally.

To enhance prevention, keep a schedule for periodic maintenance that includes testing valve operation and checking for proper alignment. Inspecting muffler tips and high-performance parts can also help identify potential issues early on. Regular attention to these details not only ensures the smooth running of your vehicle but also prolongs the life of performance brakes and other critical components, ultimately saving you time and money in the long run.

Efficient Cleaning and Maintenance Practices for Longevity

Maintaining exhaust cutout valves is an essential practice for ensuring optimal performance and longevity in automotive systems. Regular cleaning and maintenance routines can significantly extend the lifespan of these critical components, which play a pivotal role in vehicle breathing and power generation. Start by removing the valve from its housing to access all surfaces thoroughly. Use compressed air or dedicated tools to blast away dirt, debris, and carbon buildup that may have accumulated over time. This meticulous process ensures every nook and cranny is clean, addressing potential issues before they escalate.

Beyond basic cleaning, employing suitable lubricants on moving parts can prevent friction-related wear. Consider using recommended greases or oils designed for automotive applications to safeguard against corrosion and rust. Additionally, inspect gaskets and seals for any damage or degradation; replacing them promptly is crucial as compromised seals can lead to leaks and reduced engine efficiency. By combining thorough cleaning with preventative maintenance practices, you’ll ensure your high-performance parts, such as cold air intakes and air intake systems, remain in peak condition, thereby maximizing the reliability of your exhaust cutout valves.

Maintaining exhaust cutout valves is crucial for ensuring reliable performance in various industrial applications. By understanding their functionality, conducting regular inspections, and adopting efficient cleaning practices, you can significantly extend their lifespan. Implementing these maintenance tips will help prevent costly downtime and keep your exhaust cutout valves operating smoothly, contributing to overall system efficiency.