Exhaust cutout valves are vital automotive components that control exhaust gas flow, offering drivers a choice between quiet and loud exhaust notes for balanced performance and civility. Beyond cars, they're used industrially to manage noise pollution, reduce emissions, and improve engine performance, enhancing safety and efficiency in various applications.

Exhaust Cutout Valves (ECVs) are versatile components that offer a unique solution for managing gas flow. They can deliver either quiet or loud operation on demand, catering to diverse industry needs. This article delves into the basic function of ECVs and explores their advantages in various applications. Understanding these benefits enables professionals to choose the optimal cutout option, enhancing efficiency and safety across different sectors, from automotive to industrial settings.

- Understanding Exhaust Cutout Valves: Their Basic Function

- Advantages of Quiet and Loud Cutout Options Explained

- Applications and Benefits in Various Industries

Understanding Exhaust Cutout Valves: Their Basic Function

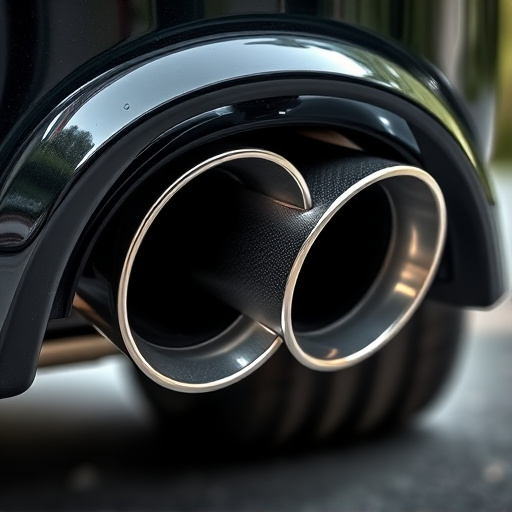

Exhaust cutout valves are an integral part of many automotive systems, playing a crucial role in controlling and managing exhaust gas flow. Their primary function is to allow for precise control over when and how much exhaust gases are released from an engine, enabling optimal performance and efficiency. These valves work by cutting off or adjusting the opening that allows exhaust gases to escape, thereby regulating the engine’s power output and sound level.

Imagine them as gatekeepers, opening and closing to let exhaust out at specific times, like a carefully choreographed dance. This precise control is particularly important for vehicles with performance-oriented setups, where minimizing noise while maximizing power is a key goal. In such cases, exhaust cutout valves can be adjusted to deliver both loud, powerful exhaust notes or quieter, smoother operation on demand, thanks to their ability to dynamically alter the exhaust gas flow.

Advantages of Quiet and Loud Cutout Options Explained

The choice between a loud and quiet exhaust cutout valve is a significant consideration for vehicle owners, each offering unique advantages tailored to diverse driving experiences. In many cases, drivers opt for a louder cutout, particularly in performance-oriented vehicles, as it enhances the driving thrill with an aggressive sound that mirrors the engine’s power. This option resonates with folks who seek an exhilarating driving experience and often aligns with high-performance parts and exhaust mufflers designed to maximize output.

On the other hand, quieter cutout valves cater to a broader range of preferences, from everyday commuters seeking a more serene journey to those living in urban areas with noise restrictions. While sacrificing some of the dramatic sound, these valves ensure a comfortable driving environment without disturbing neighbors or fellow road users. Consider it a balance between performance and civility, where drivers can still enjoy their vehicle’s power without the extraneous noise, complementing performance brakes for controlled and responsive stopping.

Applications and Benefits in Various Industries

Exhaust cutout valves find their applications across a wide range of industries, from automotive to manufacturing, catering to diverse needs for sound control and performance optimization. In the automotive sector, these valves are increasingly integrated into custom car builds and aftermarket modifications. They allow drivers to seamlessly switch between a quiet, road-friendly setting and a more aggressive, sportier exhaust note on demand. This flexibility enhances both driving experience and fuel efficiency by enabling the vehicle to operate in the most optimal mode for given conditions.

In industrial settings, exhaust cutout valves are invaluable for managing noise pollution, particularly in factories with machinery that generates significant sound levels. By strategically placing these valves in exhaust systems, operators can reduce overall noise emissions, adhering to environmental regulations and fostering a safer, more comfortable working environment. Moreover, their precision control over exhaust flow contributes to improved engine performance, including enhanced braking efficiency through better heat dissipation, as seen in high-performance brakes coupled with cat-back exhaust systems.

Exhaust cutout valves offer a versatile solution for controlling gas flow, with both quiet and loud options catering to diverse industry needs. By providing precise control over exhaust emissions, these valves contribute to improved safety, reduced noise pollution, and enhanced operational efficiency. Whether in automotive, industrial, or other applications, understanding the advantages of each cutout option enables informed decisions, ensuring optimal performance and compliance with environmental standards.