Exhaust cutout valves optimize exhaust gas flow in engines, boosting performance and fuel efficiency by controlling pressure differentials. They enhance horsepower, torque, and customization of engine sound while meeting legal standards. Combined with other upgrades, these valves significantly improve driving dynamics. Applied across automotive manufacturing and motorsports, they boost power, economy, and handling, leading to faster lap times and safer driving experiences.

Exhaust cutout valves are revolutionary components designed to optimize exhaust gas flow, offering significant benefits across various industries. This article delves into the fundamentals and advantages of these innovative mechanisms, providing a comprehensive understanding of their functionality. We explore the science behind their ability to quicken exhaust flow, showcasing their impact on performance. From automotive to industrial applications, discover how exhaust cutout valves are transforming efficiency and power delivery.

- Understanding Exhaust Cutout Valves: Basics and Benefits

- How They Quicken Exhaust Flow: The Scientific Explanation

- Real-World Applications: Improving Performance Across Industries

Understanding Exhaust Cutout Valves: Basics and Benefits

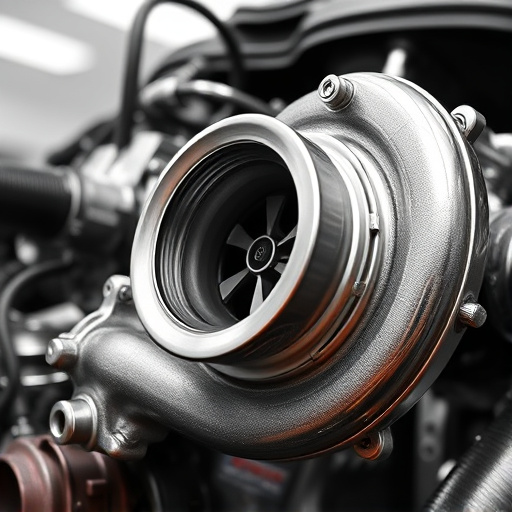

Exhaust cutout valves are specialized components designed to control and optimize exhaust gas flow within an engine’s system. They function by temporarily closing or opening specific sections of the exhaust pipe, allowing for precise adjustments to the vehicle’s performance. This simple yet effective mechanism offers several advantages over traditional exhaust systems.

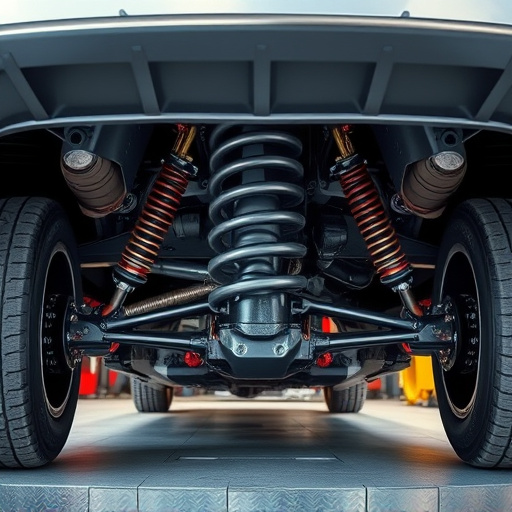

By installing exhaust cutout valves, drivers can enjoy improved engine performance and fuel efficiency. These valves enable better airflow, enhancing the combustion process and reducing backpressure in the exhaust. As a result, vehicles equipped with cutout valves often experience increased horsepower and torque, making them particularly appealing to car enthusiasts seeking enhanced driving dynamics. Moreover, their ability to control exhaust flow also benefits drivers by improving engine sound customization, allowing for a more personalized and aggressive exhaust note when desired, while still maintaining legal requirements. In conjunction with other performance upgrades like performance air filters and coilover kits, exhaust cutout valves can be a game-changer for those seeking that perfect balance between power and control on the road.

How They Quicken Exhaust Flow: The Scientific Explanation

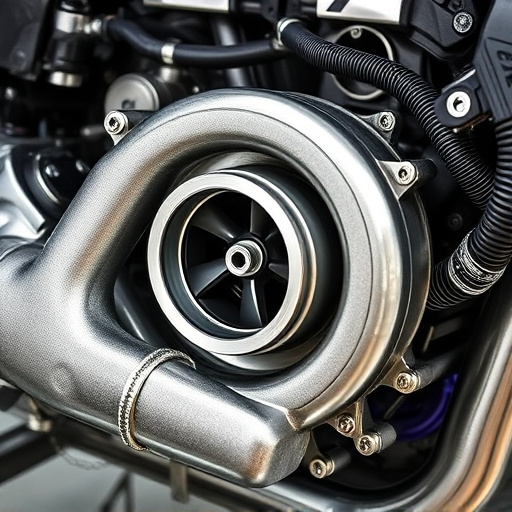

Exhaust cutout valves significantly enhance exhaust flow by facilitating a more efficient path for gases to exit the engine. When engaged, these valves selectively block or reduce the size of specific portions of the exhaust system, allowing for faster and more direct gas expulsion. The scientific principle behind this lies in the manipulation of pressure differentials within the exhaust systems. By restricting certain sections, backpressure is reduced, enabling a smoother flow of gases from the engine to the rear of the vehicle.

This effect is particularly pronounced in vehicles equipped with performance-oriented exhaust mufflers or custom exhaust systems, where optimizing gas flow can lead to substantial power gains. Even suspension components, though indirectly, play a role by ensuring smooth and rigid structural support during acceleration events, minimizing vibrations that could impede exhaust flow. As a result, exhaust cutout valves offer not just a quick fix for improving engine performance but also a fine-tuning mechanism for enthusiasts seeking the ultimate driving experience.

Real-World Applications: Improving Performance Across Industries

Exhaust cutout valves find their real-world applications across a plethora of industries, each demanding improved vehicle performance and efficiency. From automotive manufacturing to motorsports, these innovative brake components play a pivotal role in enhancing exhaust flow, thereby boosting overall engine power and fuel economy. In racing, for instance, exhaust cutout valves enable drivers to quickly adjust the flow of gases leaving the engine, allowing for precise control during high-speed maneuvers. This precise manipulation translates into enhanced acceleration and faster lap times.

Moreover, beyond the race track, these valves offer significant advantages in everyday vehicles. By strategically blocking or opening exhaust outlets, they can optimize air pressure within the system, leading to smoother operation of brake pads and improved vehicle handling. The adaptability of exhaust cutout valves makes them indispensable tools for engineers and mechanics looking to fine-tune vehicle performance, ensuring that each ride is not just faster but also safer and more responsive.

Exhaust cutout valves are a game-changer in optimizing exhaust flow across various industries. By quickly shutting off or regulating exhaust gas emissions, these valves enhance performance and efficiency. The scientific principle behind their effectiveness ensures a swift response to changing conditions, making them an indispensable tool for improving engine performance and reducing environmental impact. In real-world applications, exhaust cutout valves prove their worth, offering a simple yet powerful solution to manage exhaust gases effectively.