Exhaust cutout valves are essential automotive components that control gas flow, impact vehicle performance and sound. They offer drivers customization from powerful roars to quiet exhaust notes, enhancing acceleration and top speed when integrated with intake systems and suspension kits. These versatile valves also aid in heavy braking noise regulation and diagnostics.

Exhaust Cutout Valves: Mastering Loud or Quiet On-Demand Control

Discover the versatile role of exhaust cutout valves in managing engine sound. From quiet, refined environments to loud, powerful applications, these valves offer precise control. This article demystifies their function, explores the science behind loud and quiet operations, and guides you through ideal use cases for maximizing performance and user experience. Unlock the potential of exhaust cutout valves in various industries.

- Understanding Exhaust Cutout Valves: Their Role and Function

- The Science Behind Loud and Quiet Operations

- Applications: When and Where to Use Exhaust Cutout Valves

Understanding Exhaust Cutout Valves: Their Role and Function

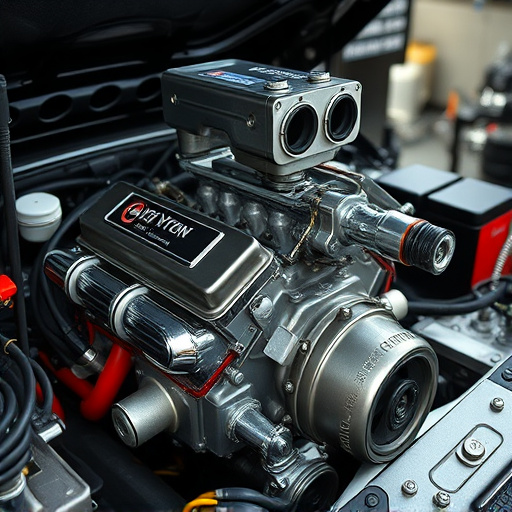

Exhaust cutout valves play a pivotal role in automotive engineering, particularly when it comes to fine-tuning vehicle performance and sound. These valves are designed to control the flow of exhaust gases, allowing for precise adjustments to both power output and noise levels. By manipulating the exhaust system, drivers can achieve either a powerful roar suitable for high-performance parts or a quieter, more refined exhaust note, depending on their preference.

In many performance vehicles, exhaust cutout valves work in conjunction with air intake systems and suspension kits to create a balanced driving experience. They enable drivers to switch between different modes, enhancing acceleration and top speed by opening up the exhaust for maximum gas flow or providing a more subtle, yet sporty, exhaust sound during everyday driving. This versatility makes exhaust cutout valves an essential component for those seeking both functionality and customization in their vehicles.

The Science Behind Loud and Quiet Operations

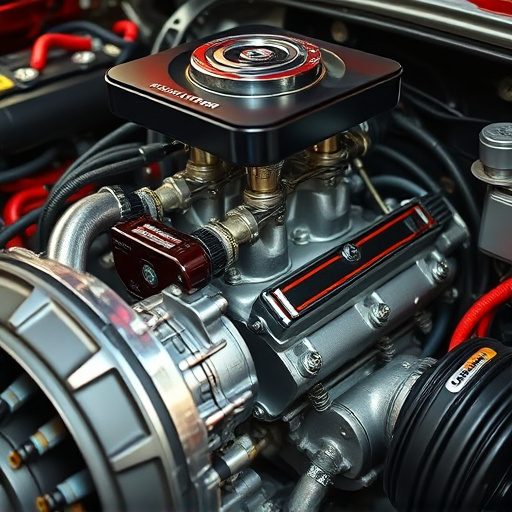

The operation of exhaust cutout valves is a fascinating interplay of engineering and acoustics. At their core, these valves control the flow of exhaust gases from an engine, influencing both power output and sound level. The science behind loud and quiet operations lies in the precise manipulation of this exhaust flow. When open, exhaust cutout valves allow for unrestricted gas discharge, resulting in a powerful, high-decibel note often desired in performance air filters and suspension kits designed to enhance driving thrill. Conversely, when closed, these valves restrict exhaust flow, significantly reducing noise levels, a feature particularly valuable in urban settings where noise pollution is a concern.

The ability to switch between these modes is facilitated by advanced mechanisms within the valve system. Air intake systems, integral to optimizing engine performance, can interact with exhaust cutout valves to fine-tune both power and sound output. This dynamic interaction allows for customized driving experiences—from the roar of a racing engine to the subdued purr of a smoothly running vehicle, all achieved through the precise control of these innovative valves.

Applications: When and Where to Use Exhaust Cutout Valves

Exhaust Cutout Valves are versatile tools with a range of applications across various industries. They are particularly useful in automotive settings, where precise control over exhaust gas flow is essential. For example, when testing or modifying vehicles, these valves allow mechanics to isolate specific components, such as the exhaust system or catalytic converter, for performance tuning or diagnostic purposes.

In addition to their use in routine maintenance and modifications, exhaust cutout valves are invaluable for high-performance braking systems. In vehicles equipped with performance brakes and advanced suspension components, these valves can help regulate exhaust noise levels during heavy braking events. By quickly adjusting the exhaust flow, they contribute to a quieter ride for passengers while still allowing for effective cooling of brake pads during intense driving conditions.

Exhaust cutout valves offer a versatile solution for controlling gas flow, delivering either quiet or loud operations as needed. By understanding their role, the science behind their functionality, and exploring various applications, you can harness the power of these innovative devices to suit your specific requirements. Whether it’s for research, industrial processes, or specialized projects, exhaust cutout valves provide a precise and adaptable method to manage gas emission, ensuring optimal performance and safety.